Hidden inefficiencies across production & packaging lines quietly drain margins and reduce competitiveness.

At Arcon Group, we see manufacturers consistently facing:

- Excess inventory and packaging waste

- Product giveaway due to inaccurate filling

- High labor and maintenance costs

Below are 5 proven ways to optimize production & packaging without compromising quality:

1. Use Generic (unprinted) Cartons

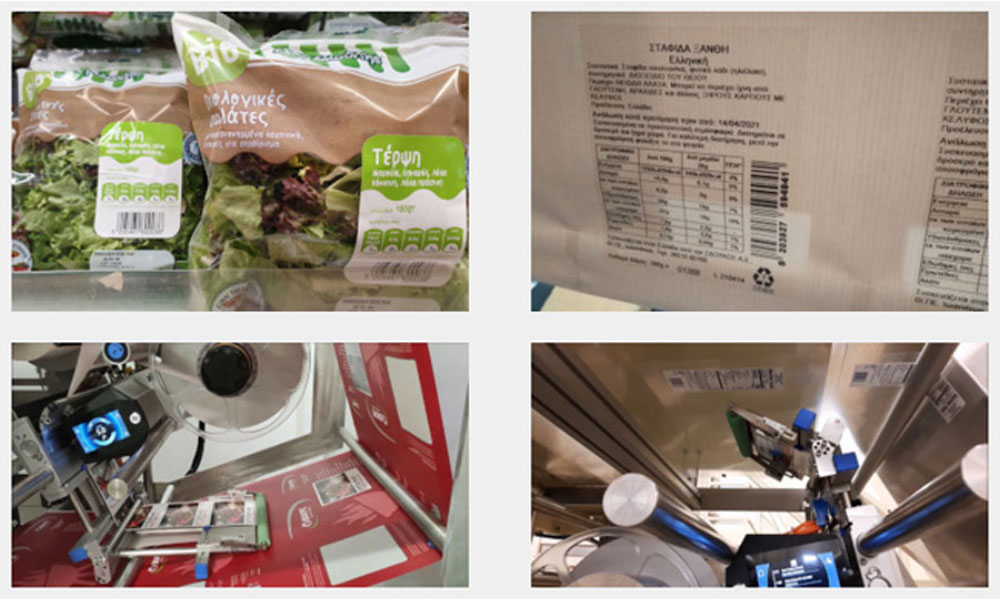

Printing variable data (product name, quantity, expiry date, LOT, barcodes, etc.) directly on the production line dramatically reduces inventory complexity and cost. This approach, known as Generic Carton Printing, is now the best practice in modern manufacturing.

2. Eliminate Overfilling through Precision Weighing

High-accuracy weighing and in-line check weighing ensure optimal fill levels, reduce product giveaway, and maintain regulatory compliance. Real-time feedback automatically corrects filling deviations.

3. Automate Coding and Labelling

Automating marking and coding, via Print & Apply systems or direct printing on packaging, reduces labor costs, minimizes errors, and ensures full traceability and compliance.

4. Introduce Robotic Palletizing

Robotic palletizing significantly lowers labor costs, increases consistency, and supports multi-line operations. Today’s systems can handle multiple packaging formats across several lines simultaneously.

5. Replace Outdated Equipment with Energy-Efficient Technology

Legacy machines consume more energy, require more maintenance, and deliver lower performance. Upgrading to modern equipment improves productivity, reduces environmental impact, and lowers total cost of ownership. Many suppliers offer attractive trade-in programs.

Please fill out the contact form or email us at