Hidden inefficiencies across production & packaging lines quietly drain margins and reduce competitiveness.

At Arcon Group, we see manufacturers consistently facing:

- High labour and maintenance costs

- Excess inventory and packaging waste

- Product giveaway due to inaccurate filling

Below are 5 proven ways to optimize production:

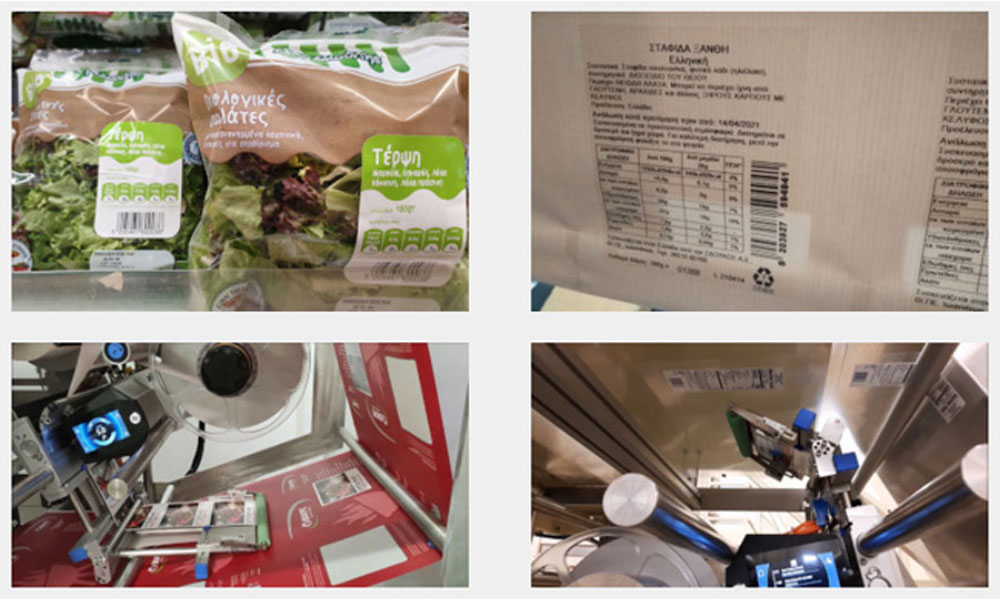

1. Automate & Verify your Coding

One way to immediately reduce hidden costs associated with wrong printing and recalls is to automate the product coding and verification process. Use central management of label designs and codes (rather than manual input at each station) and verify your codes for accuracy, readability, and correct placement as they are being produced.

2. Use Generic (unprinted) Cartons

If you use unprinted cartons and print the variable information (product name, quantity, weight, expiration date, LOT, barcodes, etc.) on them directly on the production line, you significantly reduce inventory costs. This practice, known as "Generic Carton Printing", is now being adopted by an increasing number of global manufacturing companies.

3. Eliminate Overfilling through Precision Weighing

When raw materials are weighed with high accuracy, you save materials by achieving optimal package filling. If you perform the check dynamically (in-line checkweighing), you ensure that all products have the correct weight. This is because a checkweigher detects deviations in real time and automatically feeds this information back to the filling machine.

4. Automate your Case Packing & Palletising

A significant portion of production costs can be reduced by using robotic systems to automate case packing and palletising. Modern technology allows the simultaneous handling of up to five production lines for different types of packaging. Higher productivities are also achieved when implementing such technologies.

5. Replace Outdated Equipment with Better Consumption IoT Enabled Printers

Legacy machines consume more fluids, more energy, require more maintenance, and deliver lower performance. Upgrading to modern equipment improves productivity, reduces environmental impact, and lowers total cost of ownership. At the same time new printers are IoT enabled for remote monitoring and performance optimisation. Ask your suppliers whether they offer offer trade-in programs - the terms are usually extremely favorable.

Please fill out the contact form or email us at